How to Choose the Right Industrial Blade Manufacturer for Your Industry

Your choice of industrial blade the quality of your output might be greatly impacted by the manufacturer equipment durability and effectiveness of operation. With so many producers available, choosing the best partner requires a deep understanding of the needs of your sector and the specifications for your products, and service standards.

In this post, we will walk you through the essential things to look for in an industrial blades manufacturer and explain why picking the correct one is key to long-term success.

Essential Things to Take Into Account While Selecting a Manufacturer

Choosing the right manufacturer involves evaluating several critical factors that directly impact your product’s quality, consistency, and long-term success.

Industry Experience

Seek out producers that have a track record of success in your industry. A business familiar with the specifics of your production process will be better able to suggest the right blades, coatings, and materials.

For instance, industrial blades used in metal recycling have quite different standards than those for food-grade blades. An experienced manufacturer will remain in compliance with pertinent rules in addition to understanding the operating needs.

Available Blade Types and Material Quality

The strength, longevity, and resistance to corrosion or wear of blades are determined by the raw materials used in their manufacture. Standard materials are ceramic, stainless steel, tungsten carbide, and high-carbon steel.

Consult the manufacturer:

What supplies do they employ?

Do they provide long-lasting coatings like ceramic or titanium nitride?

Can they alter the hardness of the blade to suit your needs?

You may depend on a provider for various machines and processes if they provide a choice of blade types and materials.

Technical Proficiency and Production Guidelines

To ensure a seamless blend of efficiency, precision, and user-centric innovation, the following key aspects play a vital role in upholding our technical standards and production excellence.

Personalization and Technical Assistance

Production settings vary significantly from one another. Custom engineering services, such as blade design, prototype, and on-site consultancy, are provided by a reputable manufacturer.

This capacity becomes even more crucial when your manufacturing line has particular angles, sizes, or cutting circumstances that call for customized blade geometry.

Certifications and Quality Assurance

An organization's dedication to constant quality is demonstrated by certifications like ISO 9001 or adherence to FDA, GMP, or CE requirements. Inquire about their inspection procedure and whether they offer hardness, wear resistance, and accuracy testing data.

Inconsistency or blade failure might be expensive. A robust quality assurance procedure reduces risk and guarantees dependability in each supplied batch.

Delivery and Supply Chain Dependability

An efficient and dependable supply chain ensures timely deliveries, reduces operational risks, and maintains customer satisfaction globally.

Lead times and production capacity

Delays in the delivery of blades can stop complete operations. Manufacturers with efficient supply chains and sufficient manufacturing capacity will guarantee that routine and urgent orders are fulfilled on time.

Assess the manufacturer's ability to grow with your expanding demands as well. As your company expands, a partner that can handle today's demand but isn't scalable might become a bottleneck.

Worldwide Assistance and Transportation

If your business is spread over several nations or places, choose a manufacturer with support centres and distribution networks worldwide. Local assistance lowers turnaround times and shipping expenses, particularly for urgent replacements.

After-Sale Assistance and Connection

Wear, inappropriate settings, or incorrect blade installation can all lead to cutting problems. You can address issues more rapidly and effectively if the manufacturer provides technical support and prompt customer care.

For example, it provides professional assistance and instruction to guarantee the best possible blade use and upkeep.

Conclusion

For every sector that relies on manufacturing, selecting the best industrial blade manufacturer is essential. A reliable manufacturer guarantees better blade longevity, less downtime, and dependably high-quality outputs. You can find a long-term partner who shares your manufacturing objectives and challenges by focusing on engineering support, material quality, after-sales service, and industry expertise.

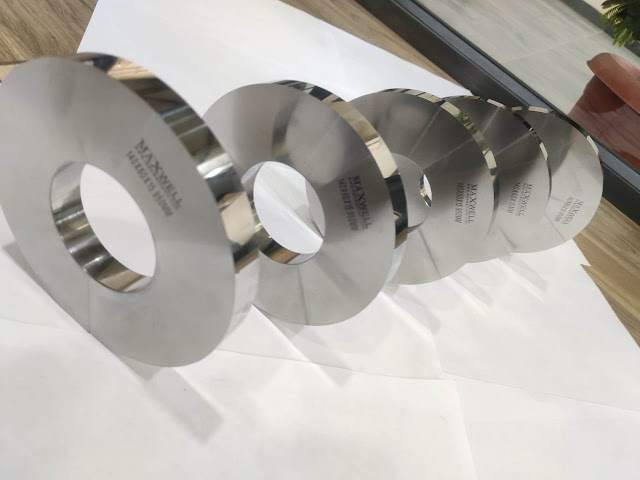

Maxwell distinguishes out in the industry with a solid reputation for offering premium industrial blades, technological know-how, and customer-first service. Maxwell provides more than just blades; they deliver the performance you can rely on, thanks to their worldwide logistics, customized solutions, and accredited quality assurance procedures.

Comments

Post a Comment