Top 10 Uses of Industrial Knives in Modern Manufacturing

In today’s fast-paced manufacturing environment, Industrial Knives are the unsung heroes behind efficiency, precision, and productivity. Whether it's cutting, slicing, shearing, or slitting, these specialized tools are central to almost every modern production line. From food processing to metal fabrication, industrial knives are built to handle high workloads with unmatched consistency.

In this detailed post, we explore the top 10 applications of industrial knives in modern manufacturing industries and why their role is indispensable in maintaining high performance and product quality.

1. Paper and Pulp Industry

One of the most extensive applications of industrial knives is in the paper and pulp sector. Here, industrial knives are used for cutting jumbo rolls, slitting paper sheets, and trimming edges to desired sizes. These knives must handle high-speed operations while delivering ultra-clean cuts to avoid paper jams and wasted material.

Speciality blades, such as slitter knives and log saw blades, are engineered to meet these requirements, thereby reducing downtime in massive production cycles.

2. Plastic and Rubber Processing

In the plastic and rubber industries, industrial knives are used for cutting moulded components, trimming flash, slitting films, and recycling operations. These knives must remain sharp and resistant to abrasion due to the harsh, flexible, and sometimes sticky nature of plastics and rubbers.

Circular knives and granulator blades are commonly used for plastic granulation and regrinding, ensuring material is reduced efficiently for reuse or further processing.

3. Food Processing Industry

Precision and hygiene are essential in food processing, making industrial knives a vital part of the industry. High-quality stainless steel knives are used for slicing meats, vegetables, bakery items, and frozen products.

These knives are designed for clean, uniform cuts, which minimize product waste and ensure food safety. In automated food processing lines, industrial knives play a crucial role in maintaining efficiency while upholding health standards.

4. Metal Fabrication and Steel Industry

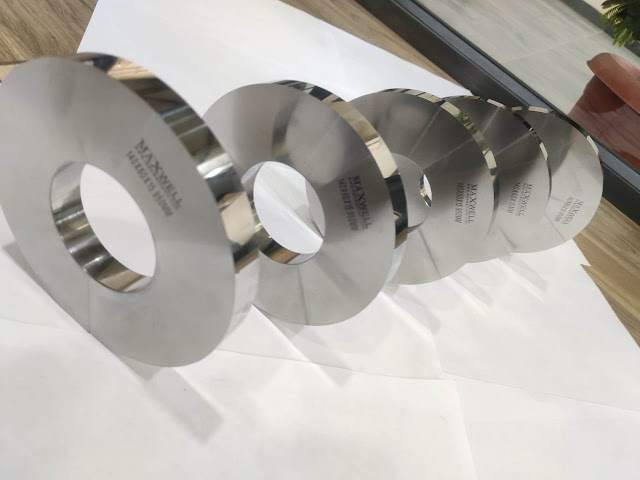

The metalworking industry uses industrial knives for cutting metal sheets, trimming edges, and slitting coils. These knives, often made from high-speed steel or carbide materials, must endure extreme temperatures, high stress, and continuous wear.

Guillotine knives and shear blades are commonly used in the fabrication of sheet metal. Their durability and cutting precision directly impact the speed and quality of the metal parts being manufactured.

5. Textile and Fabric Manufacturing

Textile manufacturers rely on industrial knives for cutting and shaping a variety of fabrics, from natural cotton to synthetic fibres. These knives must be precise to prevent fraying and maintain fabric integrity during high-speed operations.

Speciality knives, such as crush cutters and rotary slitter blades, ensure clean, repeatable cuts, which are essential for consistent fabric roll sizing and pattern cutting.

6. Packaging Industry

In the packaging industry, industrial knives are essential for cutting films, foils, cardboard, and corrugated materials. These knives are often integrated into high-speed machines that require precise cuts to maintain packaging consistency and functionality.

Whether it's making cartons, plastic wraps, or laminated packages, high-performance industrial knives play a vital role in streamlining the packaging process and reducing material waste.

7. Woodworking and Lumber Processing

The wood industry uses industrial knives for planing, chipping, and cutting wood materials. These include large guillotine blades used in sawmills to slice logs or precision knives for furniture-making.

Due to the hardness of some wood types, knives must maintain sharp edges and resist corrosion. Dull or improperly aligned blades can result in uneven cuts or material loss, affecting the final product's quality.

8. Recycling and Waste Management

In recycling plants, industrial knives are used to shred and cut materials such as metal scrap, plastics, rubber, and textiles. These knives must be durable and capable of handling contamination and irregular shapes.

Shredder blades, granulator knives, and shear cutters are widely used to convert waste into manageable pieces, which are then processed or reused. Their role is pivotal in ensuring efficient recycling operations and contributing to environmental sustainability.

9. Automotive and Aerospace Manufacturing

Precision is everything in the automotive and aerospace industries. Industrial knives are used for cutting interior materials, such as upholstery, insulation, rubber seals, and composites, used in vehicle structures.

These knives help maintain the tight tolerances and high-quality finishes needed for parts used in vehicles and aircraft. The use of CNC machines with custom blade settings ensures high repeatability and production accuracy.

10. Medical and Pharmaceutical Industry

Although less discussed, industrial knives are also crucial in the medical field, particularly in the production of medical supplies, surgical instruments, and packaging.

They are used for cutting surgical dressings, medical films, and blister packaging. These knives must meet strict health standards, be easy to sanitize, and offer clean, precise cuts without fraying or tearing.

Why the Right Industrial Knife Matters

Not all knives are created equal. The right industrial knife can dramatically increase production output, reduce waste, and improve product quality. Whether a company requires custom slitting solutions or high-precision blades, selecting the right material (such as tool steel, stainless steel, or tungsten carbide) and the appropriate edge geometry is crucial.

Manufacturers should also consider factors such as:

Blade sharpness and hardness

Corrosion resistance

Machine compatibility

Ease of replacement and maintenance

Failing to use the proper industrial knife can lead to increased downtime, higher energy consumption, and damaged goods, ultimately affecting the bottom line and customer satisfaction.

Conclusion: The Backbone of Modern Manufacturing

From delicate medical supplies to heavy-duty metal sheets, industrial knives play a central role in the functionality of modern manufacturing. Their role stretches across industries, offering unmatched precision, durability, and efficiency in high-speed operations.

As manufacturing continues to evolve with automation and innovative technologies, the demand for superior-quality industrial knives will only grow. Businesses that invest in premium blades not only boost productivity but also stay ahead of the competition.

For industry-grade slitter blades, shear knives, and custom solutions, turn to the experts at Maxwell Slitter, where performance meets precision.

Comments

Post a Comment